Design your well-being

Paruyr Sevak 5/2, Yerevan, Armenia

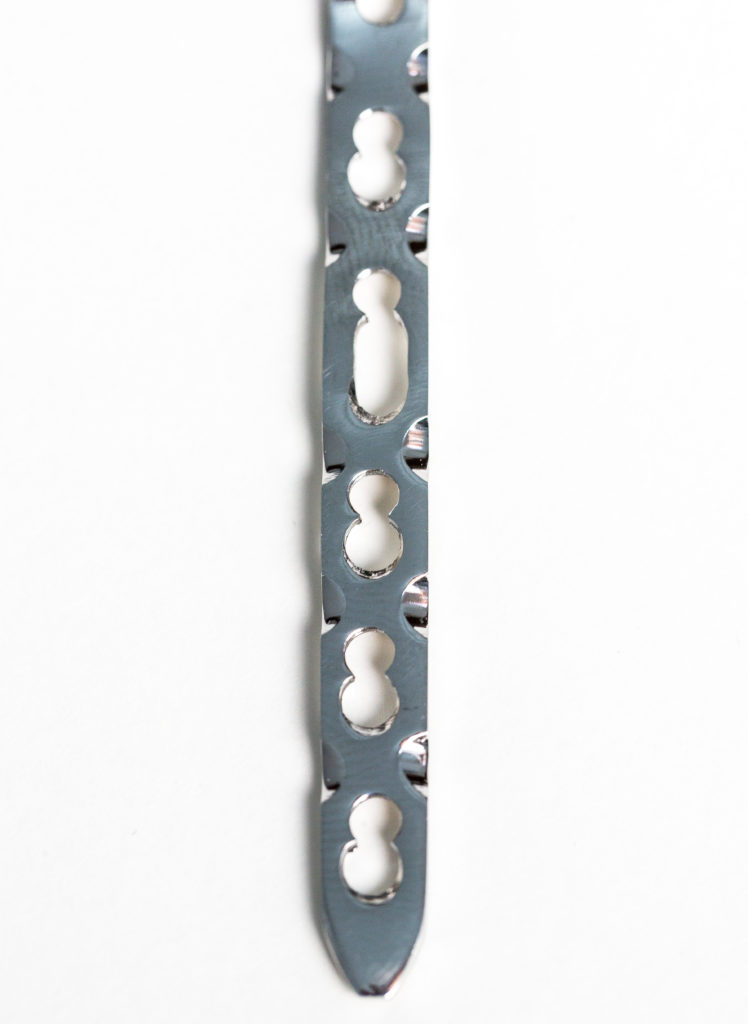

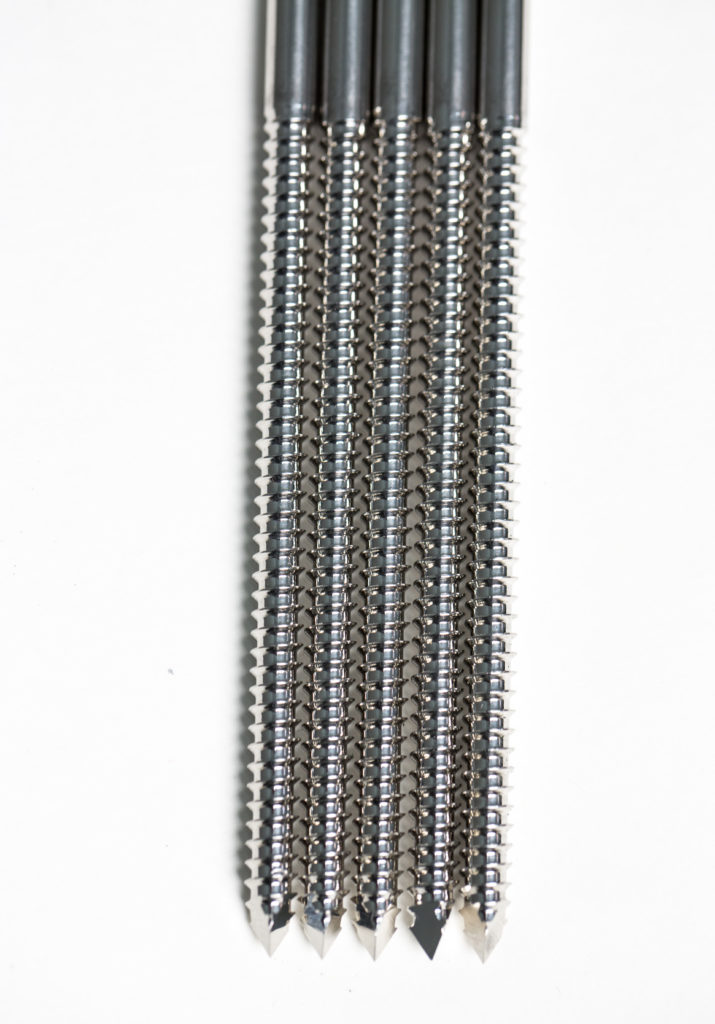

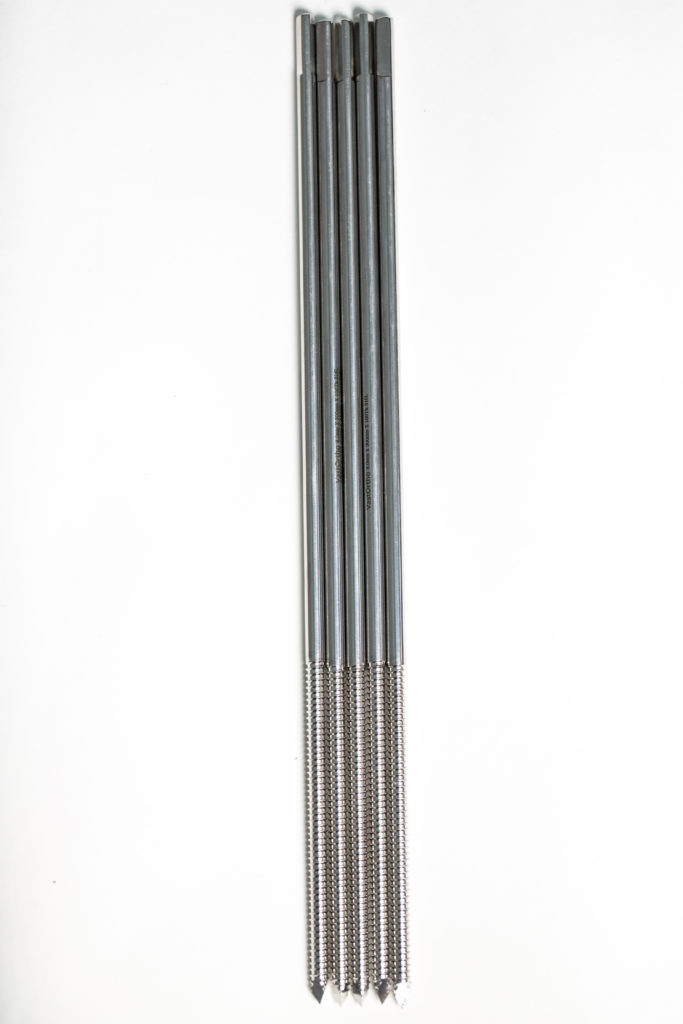

4.5mm Semi Tubular Plate, 5 holes

4.5mm Sherman

Reconstruction Plate, 4 holes

2.4 mm Locking Dorsal Distal Radius straight Plate

3.5mm Locking Pilon

Plate, 9 holes

3.5mm Locking curved reconstruction Plate, 14 hole

4.5mm Distal tibia Plate, 14 holes

3.5mm Lacking Straight Reconstruction Plate.

14 holes 300mm

3.5mm Lacking Straight Reconstruction Plate.

14 holes 200mm

3.5mm Lacking Straight Reconstruction Plate.

14 holes 300mm

3.5mm Lacking Straight Reconstruction Plate.

14 holes 200mm

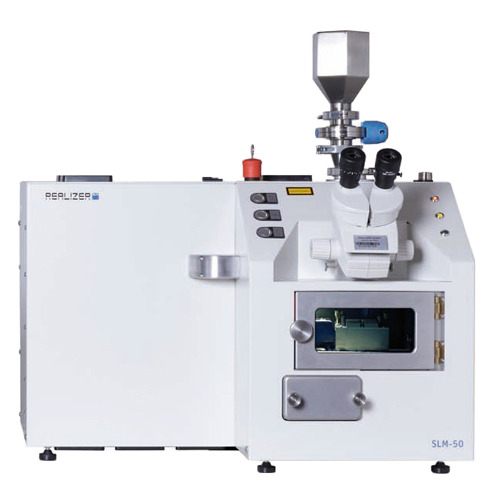

Developing First SLM Desktop Machine For Making Metal Parts.

With The SLM 50 Realizer Provides The World’s First SLM Desktop Machine For The Production Of Metal Parts. The Desktop Unit Is Designed For The Production Of Components With A Diameter Up To 70 Mm And A Height Up To 80 Mm.

As A Technology Leader ReaLizer Engages In The Development Of SLM Machines Back On Extensive Know-How And Many Years Of Experience With This Procedure. So The Developers Of Selective Laser Melting (SLM ™) 1999 Introduced The World’s First SLM Machine For Manufacturing Components Made Of Metallic Materials On The Market.

Applications

An important application for the SLM 50 is the production of crown copings, bridge frameworks or brackets made of cobalt-chrome, or gold alloys. For a conventional stump model is made after molding by the dentist first. Then the dental technician scans the model, and prepares the data for the individual components with a particular CAD software. Based on these 3D data , the SLM produces 50 exactly matching Dental parts – quickly and in high quality.The parts are absolutely true to size, one hundred percent proof and require little post-processing. On the construction platform with a diameter of 70 mm can be simultaneously up to 50 individual members finished. Compared to the conventional casting technique producing the SLM 50 starting at around 100 units per month is economically sensible.

Another practical application for the SLM 50 is the production of jewelry from different gold alloys and stainless steel.

With the optional integrated stereo microscope this device also opens universities and research institutes excellent opportunities for process monitoring. Also, various monitoring cameras are used, with and without a microscope.